Technology

Basic machines of each line:

Separation based on the nature of the polymer

- Proprietary technologies for the selection of plastics according to the type of material.

Separation by color

- The most modern optical sorting machines on the market to separate plastic particles according to color and for eventual purification from foreign bodies.

Metal separation

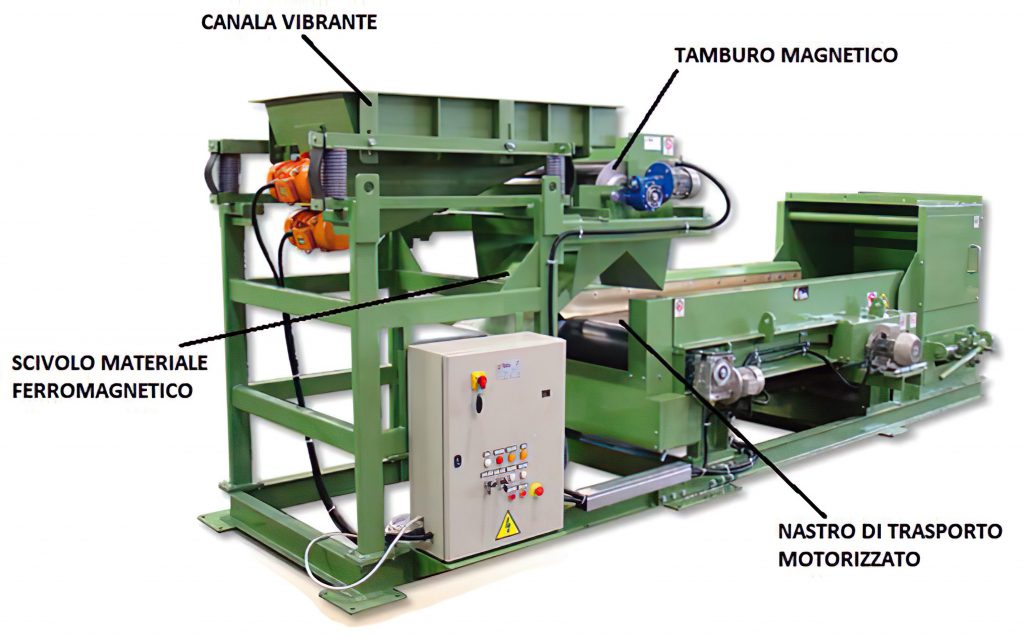

Ferromagnetic

- It is realized by means of a magnetic deferrizer.

- The material falls on a rotating drum that has a fixed magnetic core inside:

- the material is attracted by the magnetic core and remains adherent to the rotating drum throughout the sector in which the action of the core is present.

Non Ferromagnetic

- Separation of metals such as aluminum and copper is accomplished by a rotor that has magnets and rotates at high speed.

- The rotation of the magnets creates a variable magnetic field in the material in transit: if the treated parts are not ferromagnetic, induced currents are generated (Eddy Current or Foucault Current) that create a counter magnetic field with a resulting effect of repulsion.

Dust Removal

- Combining the best solutions on the market we effectively capture dust, minimizing waste.

Grinding

- We use CMG’s Budrio granulators of various sizes.

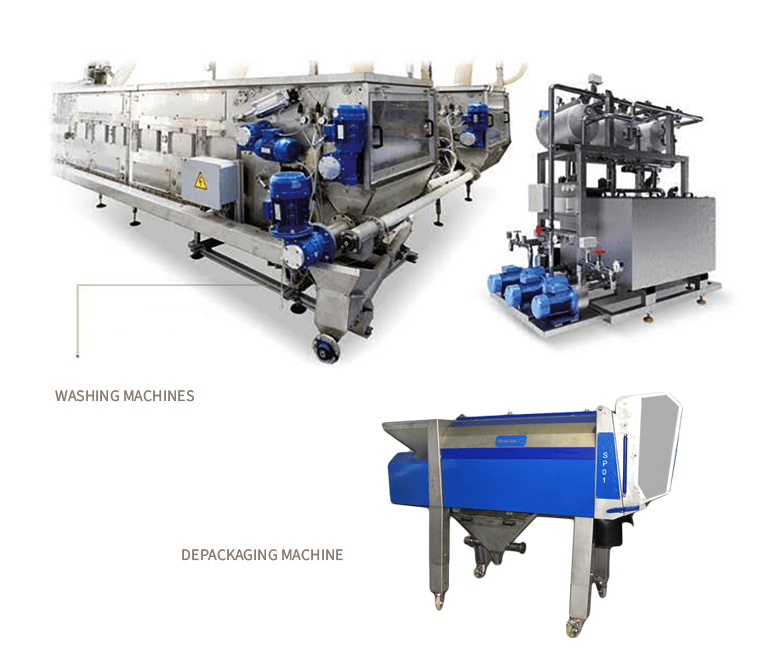

Washing and drying

- Proprietary washing and drying systems to minimize energy consumption.

Depackaging

- Proprietary machine that allows to “unpack” food by separating the food from the wrapping that surrounds it. It allows the valorization of the food and of the packaging material.

The Laboratory

Plastic Sort has an advanced laboratory to perform the following analyses:

- polymer typology (spectrometry)

- MFI

- density by means of analytical balances

- Main mechanical properties

Thanks to its partners, Plastic Sort is able to carry out the following controls:

DSC, TGA, TMA, DMA

The Lab:

- analyzes the material proposed to us to identify the most favorable process characteristics for the separation of the various polymeric fractions

- randomly checks the quality of the material during the purification phases.

Process control

Plastic Sort has sophisticated devices that allow it to continuously monitor and record the main variables of its production processes. We implement the most advanced industry 4.0 solutions, which allow us to track the processed material in the various stages of processing and to constantly verify the quality of outgoing plastics.

We contact you.

Do you need one of our services? Fill out the following form and we will contact you shortly.